Predictive Intelligence.

Don’t react – anticipate.

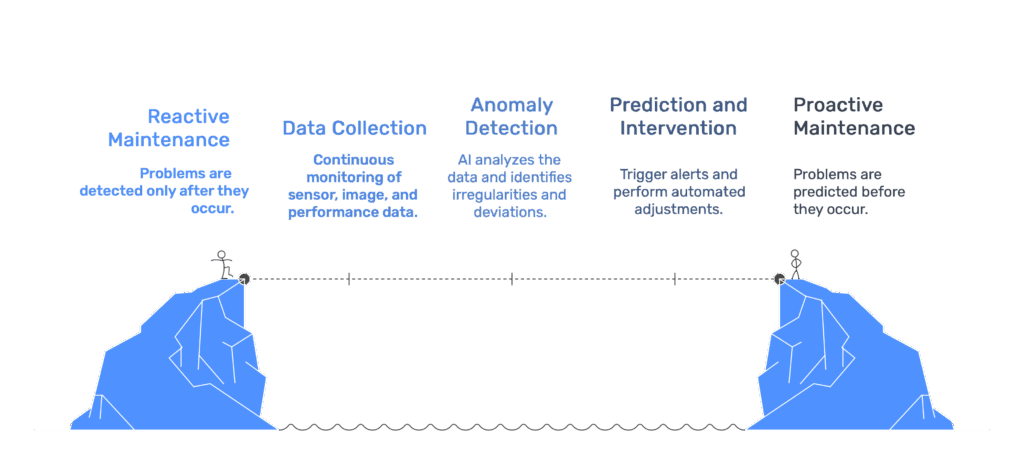

AI analyzes historical performance, sensor data, and real-time inputs to detect patterns – alerting you before a problem occurs.

How can AI help maintain quality and reliability?

By analyzing both real-time and historical data, AI identifies patterns that indicate changes in performance or product quality. This allows your company to anticipate rather than react – making maintenance more predictable and production more reliable.

How can AI help maintain quality and reliability?

By analyzing both real-time and historical data, AI identifies patterns that indicate changes in performance or product quality. This allows your company to anticipate rather than react – making maintenance more predictable and production more reliable.

With AI, quality and reliability are no longer measured afterward – they’re planned in advance.

30–50%

Maintenance cost reduction through

predictive analytics

70–90%

Fewer unplanned downtimes with

AI-based maintenance

40–50%

Fewer defects and errors through AI-driven quality control

AI sees what others notice only afterward

Artificial intelligence analyzes machine performance, sensor data, and image inputs to predict maintenance needs and quality deviations. AI not only detects changes but also recognizes the patterns that lead to errors or degradation – before they happen. As a result, maintenance becomes more predictable, production more reliable, and quality control faster and more precise – with fewer defects and interruptions.

Don’t wait for the problem – AI helps prevent it

AI analyzes historical data and real-time sensor inputs to detect the early signs of failure – before they occur. Predictive maintenance helps avoid unexpected downtime, while AI-driven quality inspection detects defective products before they enter production. This makes operations not only faster and more reliable but also more cost-efficient in the long term.

Predictive Maintenance

AI analyzes machine performance, sensor readings, and operating patterns to predict maintenance needs. The system alerts operators in time, reducing downtime, repair costs, and improving overall reliability.

AI-Powered Quality Inspection

Using camera and sensor data, AI evaluates product quality in real time. It detects defective or substandard products and automatically classifies items into quality categories – faster, more accurately, and without human error.

Related posts

See all

- AI Building Blocks

- 8 mins

- AI In Business

- 5 mins

- AI In Business

- 6 mins